About Our Mica Paper

Packing List

All information will be presented in a packing list attached to the top box on a skid or the last box on a loose shipment. The packing slip will include code, weight/ square feet, caliper, width, number of rolls per code, box number, and accumulated gross weights in as large an increment as possible under 100 lbs.

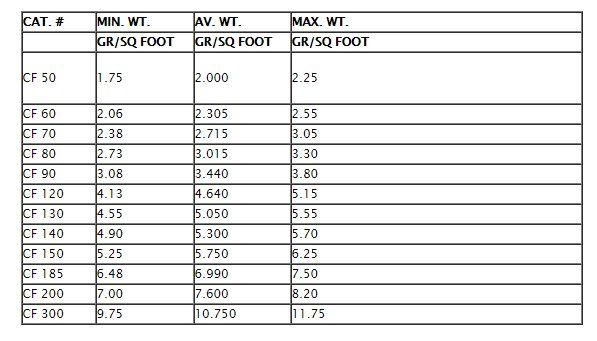

Weight

Split Spec. Max roll dia. 7.00 in.; Min. roll dia. 4.375 in.; <.0062 width; 3 in. I.D. cores.

The weight samples are dried in an oven or on a hot plate at above 100 degrees C, and weighed on a balance accurate to .01 of a gram. The sheets are labeled front, center, back. The sheets are weighed hot as a group and divided by four for the average. The individual sheets are weighed, the values recorded, and the range calculated. The average value is used on the quality shipping report. The individual values and the range are used for our in-house process control. Weight is a far more accurate measure than caliper. The variables are accurate cutting, the balance, and drying, all controllable variables. Most engineering specifications read and control the average weight in grams / square feet, quality control inspectors have taken a one inch wide strip by 12 feet, weigh it, and say this is the average weight. not so, our values are based on the master roll and the individual 6 inch x 24 inch sheets. If an individual sheet falls outside of a specification that part of the web or the roll is rejected internally. This same reasoning is applied to caliper, however, here we have the standard deviation to estimate the population and the sheet compliance to specification. It is very possible to have a dramatic (.05 mil) change in caliper from one inch to another. this is the result of stacking the deviation 10 times. This is not likely to occur in the actual caliper where four to six rolls across the web are stacked.

Based on the average of (3) six by twenty four inch samples. These are sampled every six inches across the machine.

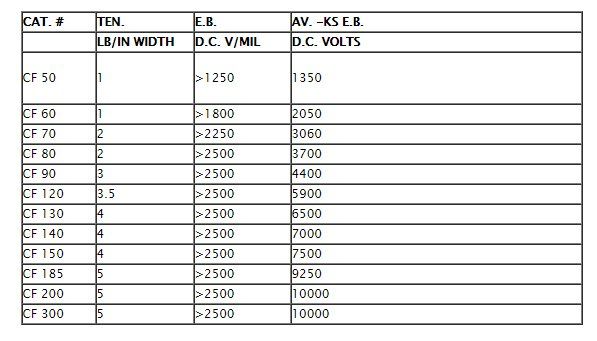

Tests are based on breaking down 16 two layer test caps at 500 volts/ sec. Rise. The caps are wound on a 1.375 dia. Mandrel. The foil is 1.75 inches by app. 72 inches. The corona film is 2.5 inches wide.

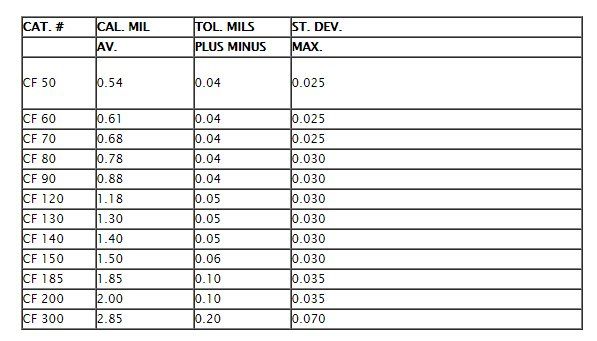

Caliper

The caliper is measured as per ASTM D-374 method C with added techniques. Ten layers are used in all cases. The measurement obtained is a result of the weight of MICA, the surface finish of the sheet, the relative humidity, the acceleration of the drop, the settling time of the anvil, the temperature, plus unknown variables. For quick results, it is best to dry the sheets above 60 degrees C before conditioning at 23 degrees centigrade and 50% RH; this lets the MICA paper come back to the test humidity level rather that dry down to it. Storing the rolls at measuring conditions for 24 to 48 hours prior to testing is an excellent technique. Our procedure is to settle the micrometer on the sheet, lift it off (.3 of a mil) until the sheet can be pulled to the test mark and dropped ( not let down- dropped). The operation is repeated across the sheet; the average calculation and the standard deviation are calculated and recorded with N, the number of readings. The value shown on our quality shipping report is the closest or the same as the outside of the slit roll. Off machine slitting if a 25 lb. master roll the values would be those at the start of the roll. For a 50 lb. master roll the first cut of the slit roll would end at the center of the master roll the second cut would end at the end of that roll. This would be the value on your shipping quality report.

Average Caliper

Based on test at one inch intervals across each master roll.

241 Dudley Road West Townsend MA 01474

Phone: 978-597-6444 Fax: 978-597-5685

Website Design & Maintenance by Kreative Dezign Studio